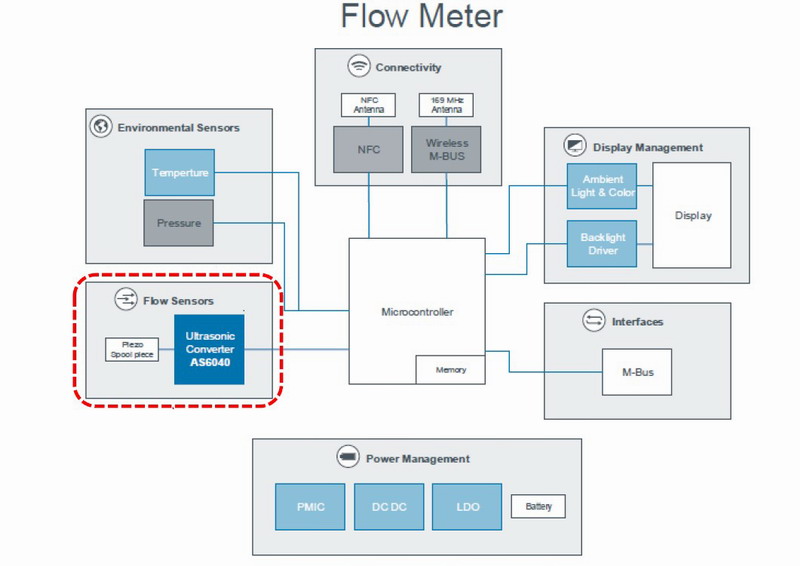

Flow measurement is the core of the whole gas meter. The flow measurement of ultrasonic gas meter generally includes three parts, ultrasonic metering circuit, transducer and pipe section. Mushen's gas meter flow measurement solution based on as6040 mainly focuses on the front-end metering circuit to solve the problem of stable input under weak signal, customize the external amplification circuit, avoid the increase of power consumption, reduce the development difficulty of customers and increase the reliability of products. It mainly includes the following:

1. 3.6V disposable battery is used for battery power supply, and the minimum working voltage is 2.8V;

2. The metering adopts Ruigan as6040, with internal integrated charge pump, adjustable voltage from 5.6v to 18V, TDC accuracy of 11ps and low power consumption design。

3. External amplifier circuit: the operational amplifier ms001 and LDO MS004 jointly customized with Shengbang micro are used for gas meter industry and can be controlled by GPIO of as6040;

4. MCU adopts um3213-bcqf (qfn24) low power chip of unicmicro:

a) 0.7μA@3.0VDeepSleep+RTC pattern

b) 110μA/MHz@3.0V @32MHz Active

5. A high-precision temperature measurement chip ens210 is configured, with temperature measurement accuracy of ± 0.15 ° C and temperature measurement range of - 40 to 100 ° C。

The whole scheme provides a simple and easy-to-use framework for sensor configuration and pipe section setting, so that developers can quickly obtain sensor flow data as long as they power up the sensor evaluation board, and display the results in graphical or digital format through the upper computer, which can configure as6040. It also provides sample code for as6040 to communicate with unicmicro um321x microcontroller, including library files for configuration download, initialization and data reading。

East Senya also has a R & D team dedicated to the research of ultrasonic measurement technology. The overall scheme is considered from many aspects such as circuit design, selection of main control chip, accuracy, power consumption and cost, so that it can be quickly integrated into the customer's product device, saving the system development time for the customer, so that it can focus more on the improvement of application characteristics in the range of flow and ambient temperature, It can develop ultrasonic gas meter with high performance and quality faster.。